In an era where sustainability and circular economy models are reshaping the manufacturing landscape, plastic recycling has become a cornerstone of modern waste management. Among the numerous types of equipment used for plastic recycling, disc type PP grinders (Polypropylene grinders) are gaining increasing attention due to their efficiency, reliability, and versatility in processing plastic waste.

This article explores the key features that make disc type PP grinders ideal for plastic waste recycling and introduces Wuxi Songhu Xinrui Machinery Co., Ltd., a professional manufacturer of high-performance PE milling machines and PVC crusher equipment that is at the forefront of this important industry.

Understanding Disc Type PP Grinders

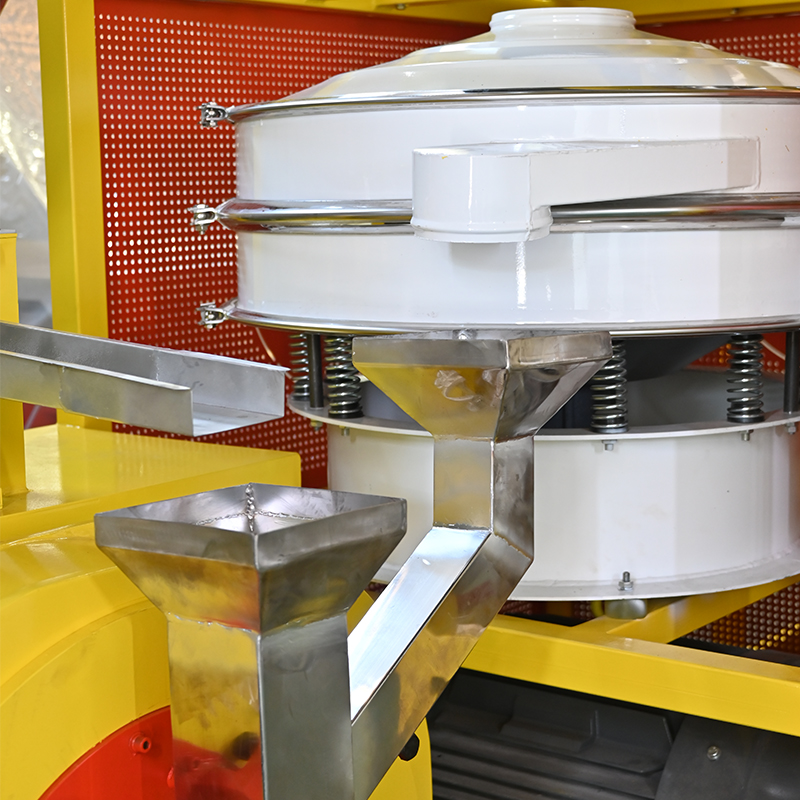

Disc type PP grinders are specialized machines designed to grind, mill, or pulverize polypropylene (PP) plastic into fine, reusable powder or granules. These machines typically use a rotating grinding disc to reduce the size of plastic flakes or scraps, making them suitable for reprocessing in the production of plastic films, pipes, containers, and other products.

Unlike conventional crushers or shredders, disc grinders offer finer grinding capabilities and are often used as the final step before plastic material re-enters the production cycle.

Key Features That Set Disc Type PP Grinders Apart

1. High Precision Grinding Discs

The core component of any disc type grinder is its grinding disc. These discs are engineered with high wear resistance, often made from hardened steel or alloy materials. High-speed rotation ensures that PP flakes are reduced to uniform powder size efficiently.

Wuxi Songhu Xinrui Machinery Co., Ltd. utilizes precision CNC technology in the design and production of grinding discs, resulting in superior cutting performance and long service life.

2. Adjustable Gap and Particle Size Control

One of the standout features of disc type grinders is the ability to control the grinding gap, which determines the final particle size. Operators can adjust the clearance between the fixed and rotating discs to meet specific granule requirements.

This flexibility is particularly valuable in applications where consistent particle size is critical, such as in film extrusion or injection molding processes.

3. High Output with Low Energy Consumption

Modern disc grinders are designed for high efficiency, allowing for large-scale plastic waste processing while keeping energy use minimal. The motor and disc system is optimized for maximum material throughput with minimal loss of power.

Wuxi Songhu Xinrui’s grinders are built with energy-saving motors and optimized air flow systems that reduce operational costs without compromising performance.

4. Integrated Cooling Systems

Grinding plastic generates significant heat. Excessive heat can cause melting or degradation of the material, especially in sensitive thermoplastics like PP. To address this, disc grinders are equipped with air or water cooling systems to maintain optimal operating temperatures.

Wuxi Songhu Xinrui offers models with efficient internal cooling channels, ensuring safe and stable operation during continuous processing.

5. Easy Maintenance and Operation

Ease of maintenance is crucial in high-volume processing environments. Disc type grinders are typically designed for quick access to internal components, such as discs, screens, and bearings, reducing downtime and improving machine longevity.

User-friendly interfaces and control panels make daily operation straightforward, even for less experienced operators.

6. Versatility Across Plastic Types

While optimized for polypropylene, disc type grinders are also capable of processing other thermoplastics such as:

PE (Polyethylene)

PVC (Polyvinyl Chloride)

ABS (Acrylonitrile Butadiene Styrene)

HDPE and LDPE

Wuxi Songhu Xinrui’s grinders are modular and adaptable, allowing customers to process multiple plastic types with minimal equipment adjustments.

Applications of Disc Type PP Grinders

Disc type PP grinders are used in a wide range of plastic waste recycling applications, including:

Reprocessing of plastic film and sheet waste

Grinding of injection molding sprues

Pulverizing blow-molded containers

Recovery of production scrap from factories

Creating feedstock for plastic compounding

With increasing regulatory pressure to reduce plastic waste, industries across packaging, automotive, electronics, and consumer goods are incorporating grinders into their recycling workflows.

Wuxi Songhu Xinrui Machinery Co., Ltd: Your Partner in Plastic Recycling Technology

As a professional manufacturer of PE milling machines and PVC crusher equipment, Wuxi Songhu Xinrui Machinery Co., Ltd. brings years of experience and innovation to the plastic recycling industry. The company offers:

High-performance disc type PP grinders with customizable configurations

Durable and precise grinding components

Energy-efficient designs tailored to customer needs

Comprehensive support, including installation, training, and maintenance

With a strong reputation for quality, reliability, and technical support, Wuxi Songhu Xinrui has become a trusted name among recyclers and plastic manufacturers both domestically and internationally.

Conclusion

As plastic recycling becomes increasingly essential in a resource-conscious world, investing in the right grinding equipment is crucial for maximizing efficiency and product quality. Disc type PP grinders offer a powerful, flexible, and cost-effective solution for transforming plastic waste into valuable raw material.

With robust features such as high-precision grinding, cooling systems, and user-friendly controls, these machines are the ideal choice for high-volume, high-quality plastic reprocessing.

Wuxi Songhu Xinrui Machinery Co., Ltd. stands ready to support your recycling operation with advanced technology, customized equipment, and expert service—empowering you to turn plastic waste into sustainable opportunity.

Top Applications of PE Pulverizers in Plastic Recycling and Processing

www.songhuxr.com

Wuxi Songhu Xinrui Machinery Co., Ltd.