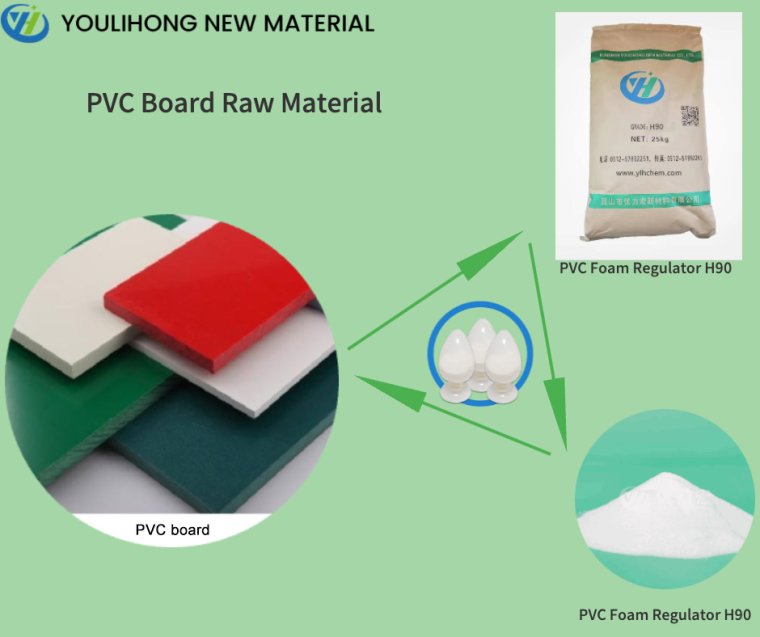

In the world of PVC foam production, achieving the perfect balance of foam structure, product strength, and surface finish is essential. Whether you're manufacturing PVC foam boards, WPC panels, or SPC flooring, one critical ingredient plays a decisive role in your formula’s performance: the PVC foam regulator.

As a leading innovator in polymer additives, Youlihong New Material Co., Ltd. specializes in the development, production, and technical support of high-performance additives for the PVC and rubber-plastic industries. With a wide range of products including foam regulators, calcium-zinc stabilizers, processing aids, lubricants, and plasticizers, Youlihong helps manufacturers fine-tune their formulations to meet precise production and quality standards.

In this article, we’ll break down how to choose the right PVC foam regulator and what factors to consider for optimal results in your specific foam production application.

What Is a PVC Foam Regulator?

A PVC foam regulator (also called a foaming modifier) is a specialized processing aid used to control the foaming behavior, melt strength, and surface quality of PVC during the extrusion or molding process. It is commonly used in the production of:

-

Foamed PVC sheets and boards

-

WPC (Wood-Plastic Composite) products

-

SPC (Stone-Plastic Composite) flooring

-

PVC ceiling and wall panels

Key Functions of a PVC Foam Regulator

Choosing the right foam regulator ensures your end product achieves the desired:

-

Foam structure uniformity

-

Cell distribution and density

-

Surface smoothness

-

Dimensional stability and mechanical strength

-

Processing efficiency and output consistency

With Youlihong New Material Co., Ltd., you benefit from a line of foam regulators specifically engineered for compatibility with both free-foamed and co-extruded PVC products.

Factors to Consider When Choosing a PVC Foam Regulator

1. Product Type and Application

Different PVC applications require different regulator types. For instance:

-

SPC flooring needs a regulator with high thermal stability and melt strength.

-

WPC decking benefits from a regulator that promotes uniform cell structure and weather resistance.

-

PVC foamed boards require a regulator that balances fluidity and rigidity.

Youlihong offers application-specific solutions for SPC, WPC, and general PVC foaming, ensuring that each additive is tailored to your unique production needs.

2. Foaming Degree and Density Control

The level of foaming you want (high, medium, or low) will determine the amount and type of foam regulator needed. The right additive helps:

-

Reduce density without compromising strength

-

Control cell size and distribution

-

Enhance foam stability under high-temperature processing

Youlihong's regulators are carefully formulated to support low-density yet high-strength production.

3. Processing Conditions

Extrusion speed, temperature profiles, and equipment type all impact foam quality. Foam regulators from Youlihong are designed to perform well under varying processing conditions, with:

-

Excellent thermal stability

-

Improved melt elasticity

-

Compatibility with Ca-Zn stabilizers and lubricants

These characteristics ensure smooth extrusion, low defect rates, and improved product yield.

4. Formulation Compatibility

A foam regulator must work seamlessly with other ingredients in your PVC formulation—such as:

-

Stabilizers (e.g., Ca-Zn stabilizers)

-

Blowing agents

-

Lubricants and impact modifiers

Youlihong offers complete formulation guidance and technical support to ensure optimal synergy among all additives used in your production.

Why Choose Youlihong New Material Co., Ltd.?

With years of experience in additive chemistry and a dedicated R&D team, Youlihong is more than just a supplier—it’s your technical partner. Their foam regulators are:

-

Proven in industrial-scale production

-

Customizable for your specific application

-

Backed by responsive technical support and formulation services

In addition to foam regulators, Youlihong provides a full suite of PVC processing aids, including defoamers, plasticizers, calcium-zinc stabilizers, and lubricants—making it easier for manufacturers to streamline sourcing and improve consistency across production runs.

Final Thoughts

The right PVC foam regulator can dramatically improve your product quality, reduce waste, and boost production efficiency. With expert support and precision-engineered additives from Youlihong New Material Co., Ltd., your foam production can reach new levels of performance and profitability.

www.ylhchem.com

Youlihong New Material(KunShan) Co.,Ltd.