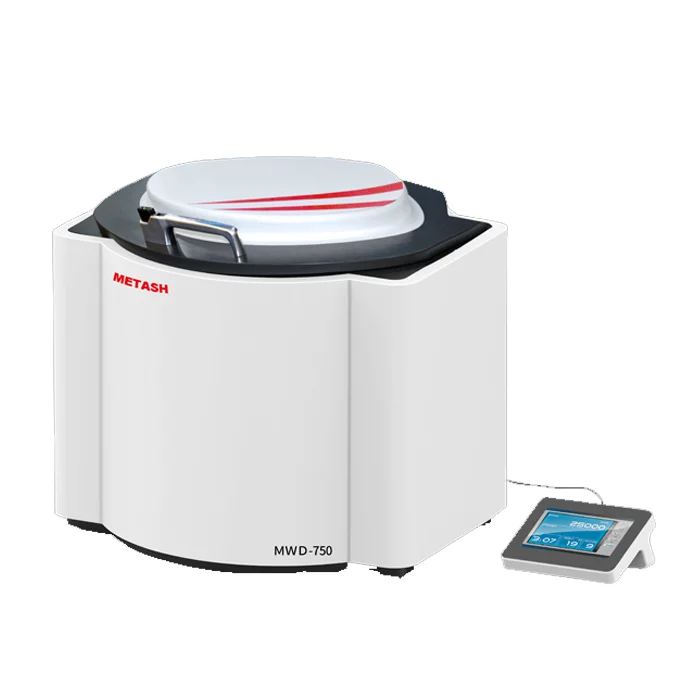

In modern analytical laboratories, sample preparation is a crucial step in ensuring accurate and reproducible results. Among various sample preparation techniques, microwave digestion has emerged as a high-performance method for digesting a wide range of complex samples, including environmental, biological, geological, and industrial materials. Microwave digestion systems offer rapid, precise, and efficient digestion while ensuring the safety and reproducibility of results. In this blog post, Metash will share the applications of high performance microwave digestion system in laboratory settings, discussing their principles, advantages.

Principles of Microwave Digestion System in Laboratory

Microwave digestion is based on the principle of heating samples using microwave energy in a closed vessel system. The system consists of:

- A microwave generator that produces electromagnetic radiation in the 2.45 GHz range.

- A pressure-resistant digestion vessel made from materials such as PTFE or quartz.

- Temperature and pressure sensors that monitor and control the digestion process.

Microwave energy excites polar molecules in the sample and digestion acid, generating heat rapidly and uniformly. The high temperatures (up to 300°C) and pressures (up to 100 bar) achieved in closed vessels facilitate the complete breakdown of complex matrices, leading to efficient sample dissolution.

Advantages of High Performance Microwave Digestion System

1. Enhanced Digestion Efficiency

High-performance microwave digestion significantly improves digestion efficiency compared to conventional methods (e.g., hot plate or open-vessel digestion). The rapid heating and homogeneous energy distribution result in faster decomposition of organic and inorganic matrices, ensuring complete dissolution in a short time.

2. Improved Safety

Modern microwave digestion systems incorporate advanced safety features such as:

- Real-time temperature and pressure monitoring.

- Explosion-proof vessels with automatic venting mechanisms.

- Automated shut-off systems in case of overpressure or overheating.

These features minimize the risks associated with handling aggressive acids under high-temperature and high-pressure conditions.

3. Reproducibility and Accuracy

Precise control of digestion parameters ensures reproducibility across multiple samples. High-performance microwave digestion systems allow for uniform heating and controlled reaction conditions, reducing variability between sample runs.

4. Reduced Reagent Consumption

Since microwave digestion occurs in closed vessels, there is minimal loss of volatile components. The closed system also allows the use of smaller volumes of concentrated acids, reducing reagent costs and minimizing laboratory waste.

5. Versatility in Sample Preparation

Microwave digestion systems can handle a wide range of sample types, including:

- Environmental samples (soil, sediments, wastewater sludge, and plant tissues).

- Biological samples (blood, urine, tissues, and food products).

- Industrial samples (metals, alloys, ceramics, and polymers).

- Geological samples (rocks, minerals, and ores).

Applications of Microwave Digestion System in Laboratory

1. Elemental Analysis via ICP-OES and ICP-MS

One of the primary applications of microwave digestion is the preparation of samples for elemental analysis using Inductively Coupled Plasma Optical Emission Spectroscopy (ICP-OES) and Inductively Coupled Plasma Mass Spectrometry (ICP-MS). The complete dissolution of samples ensures accurate quantification of trace and ultra-trace elements.

2. Total Metal Analysis in Environmental Testing

Environmental laboratories use microwave digestion for determining total metal concentrations in water, soil, and air particulate samples. Regulatory agencies such as the EPA recommend microwave-assisted acid digestion protocols (e.g., EPA Method 3051A and 3015A) for sample preparation.

3. Pharmaceutical and Nutraceutical Testing

Microwave digestion is widely used in pharmaceutical quality control for digesting drug formulations and nutraceuticals. Heavy metal impurities in drugs, as regulated by USP <232> and <233>, can be effectively analyzed after microwave-assisted digestion.

4. Food and Agricultural Analysis

In food safety testing, microwave digestion is used for elemental analysis of food products and agricultural commodities. This is crucial for assessing contaminants such as lead, arsenic, and cadmium, as well as essential nutrients like calcium, magnesium, and iron.

5. Forensic and Clinical Applications

Forensic toxicology and clinical research rely on microwave digestion for processing biological samples to detect toxic metals and essential trace elements in blood, hair, and tissues.

Conclusion

High-performance microwave digestion systems play a vital role in modern laboratory analysis, offering rapid, efficient, and safe sample preparation across diverse applications. By leveraging the advantages of precise temperature and pressure control, laboratories can achieve accurate, reproducible, and reliable analytical results. Implementing best practices in microwave digestion ensures compliance with regulatory standards and enhances the overall quality of elemental analysis.

www.metashcorp.com

Metash