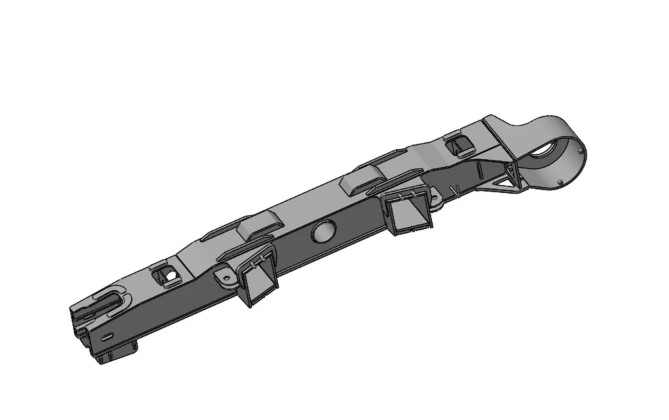

Introduction: Track Frames as the Backbone of Machinery

In heavy-duty industries such as construction machinery, agricultural machinery, special vehicles, energy, and automotive manufacturing, the track frame plays a central role. As the backbone of crawler-based equipment, track frames must withstand enormous stress, ensure stability, and deliver long service life under extreme operating conditions. Achieving these qualities requires not only high-grade materials but also advanced processing technologies that guarantee precision at every stage of production.

Hengli, a modern processing enterprise specializing in the integration of the metal supply chain, provides a comprehensive solution for track frame manufacturing. With services including laser cutting, flame cutting, plasma cutting, bending, forming, welding, robotic welding, CNC machining, painting, powder coating, and galvanizing, Hengli combines technical excellence with efficiency to meet global demands for high quality, short lead times, and competitive pricing.

Step 1: Material Preparation and Steel Plate Selection

Every strong track frame begins with the right raw materials. Selecting the appropriate steel plate is crucial to achieving the balance of strength, toughness, and machinability. Hengli’s supply chain integration ensures:

-

Reliable sourcing of high-strength steels.

-

Rigorous quality inspection of incoming materials.

-

Pre-treatment to remove impurities and prepare surfaces for cutting and welding.

By starting with carefully selected materials, Hengli sets the foundation for track frames that meet international standards for durability and performance.

Step 2: Laser Cutting, Flame Cutting, and Plasma Cutting Applications

Precision cutting defines the shape and structural integrity of the track frame. Different projects demand different cutting technologies, and Hengli integrates all three methods:

-

Laser Cutting: Ideal for thin-to-medium steel plates, offering high precision and minimal heat distortion.

-

Flame Cutting: Suitable for very thick plates, ensuring reliable cuts on heavy-duty sections.

-

Plasma Cutting: Highly versatile for medium-thickness materials, balancing speed and accuracy.

By combining these technologies under one roof, Hengli ensures flexibility and cost-effectiveness for a wide range of track frame designs.

Step 3: Bending and Forming Precision

Once the plates are cut, precision bending and forming give the track frame its structural geometry. This stage is critical because even minor inaccuracies can lead to stress points or reduced load-bearing capacity.

Hengli utilizes advanced CNC-controlled bending machines to achieve:

-

Consistent angles and curves.

-

Reduced stress concentration in critical load zones.

-

High repeatability across large production batches.

Through precise forming, the track frame gains the strength and rigidity required for demanding working conditions.

Step 4: Welding and Robotic Assembly Integration

Welding is the heart of track frame processing, where individual components come together into a unified structure. Hengli applies both manual and robotic welding depending on project requirements:

-

Manual Welding: Applied for complex joints requiring skilled craftsmanship.

-

Robotic Welding: Ensures speed, uniformity, and consistent penetration for large-scale production.

This combination maximizes both strength and efficiency, reducing the risk of defects while enhancing overall frame stability. Automated inspection systems further ensure welding integrity, minimizing rework and extending product lifespan.

Step 5: CNC Machining and Finishing Touches

After assembly, the track frame undergoes CNC machining to refine critical dimensions and attachment points. This ensures compatibility with other machine components such as rollers, idlers, and sprockets. Hengli’s CNC capabilities deliver:

-

High-precision tolerances for seamless assembly.

-

Smooth finishes for reduced wear on connected components.

-

Adaptability to custom specifications for different industries.

The finishing stage also includes surface treatments such as painting, powder coating, and galvanizing, which protect the frame from corrosion and extend operational life in harsh environments.

Conclusion: Hengli’s Streamlined, End-to-End Process

From raw material selection to the final protective coating, every step in track frame processing contributes to the performance and reliability of heavy machinery. By integrating cutting-edge technologies—laser cutting, plasma cutting, flame cutting, bending, robotic welding, CNC machining, and surface finishing—Hengli provides a one-stop solution for global manufacturers.

With advanced machines, strict quality standards, and a vertically integrated supply chain, Hengli ensures not only high quality and durability but also short lead times and competitive costs. For industries that depend on robust track frames, Hengli delivers engineering excellence from start to finish.

www.hlmetal.net

Hangzhou Hengli Metal Processing Co.,Ltd.